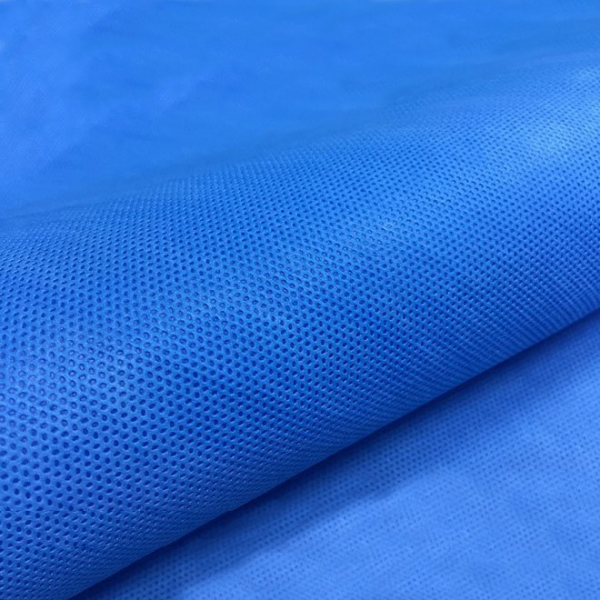

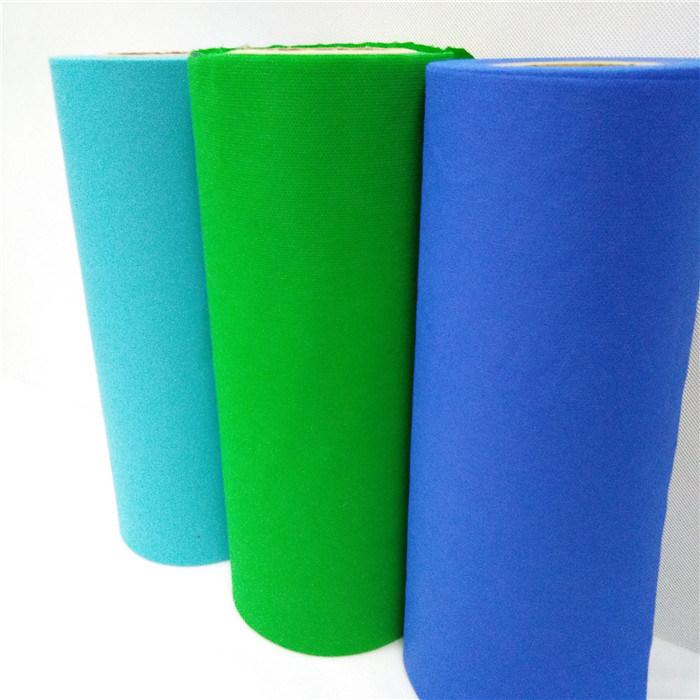

NonWoven laminated SMS fabric

Price 185.0 INR/ Kilograms

NonWoven laminated SMS fabric Specification

- Treatment Type

- Antibacterial / Antistatic / Hydrophobic / Lamination

- Product Type

- NonWoven Laminated SMS Fabric

- Shape

- Rolls / Sheets

- Color Code

- Blue, White, Green (Custom available)

- Use

- Gowns, Drapes, Masks, Coveralls, Disposable Sheets

- Properties

- High barrier protection, Breathable, Soft touch, Liquid repellent

- Application

- Medical, Industrial, Hygiene, Packaging

- Material

- SMS (Spunbond-Meltblown-Spunbond) Nonwoven

- Suitable For

- Healthcare, Laboratories, Industrial Safety

- Function

- Barrier material for protection against fluids and particles

- Compliance

- Meets ISO 13485 and EN 13795 standards

- Fabric Structure

- 3-layer SMS structure with lamination

- Edge Type

- Ultrasonic or stitched edges

- Safe for Skin

- Hypoallergenic, non-irritant

- Air Permeability

- Good breathability maintained after lamination

- Sterilization Method

- Can be EO, Gamma, or Steam sterilized

- Lamination Type

- PE or PP film laminated (customizable)

- Microbial Barrier

- High bacteria and particle filtration efficiency

- Customization

- Available in various GSM, color, lamination and packaging options

- Waterproof Level

- Water repellency >80% depending on lamination

- Tear Resistance

- Excellent tensile and tear strength

NonWoven laminated SMS fabric Trade Information

- Minimum Order Quantity

- 1000 Kilograms

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- ROLL FORM

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO13485

About NonWoven laminated SMS fabric

Melt blownnonwovens can exhibit good absorbent properties. The fine fibers can quickly absorb liquids, making them useful in applications such asabsorbent pads, wipes, and filtration media for oil filter elements.Advanced Multilayer Protection

Featuring a 3-layer SMS structure with customizable PE or PP lamination, this fabric delivers a remarkable barrier against bacteria, particles, and fluids. It is particularly suited for safeguarding healthcare professionals, industrial workers, and hygienic packaging. The lamination enhances water repellency while retaining comfort and breathability.

Certified Safety and Compliance

Every batch strictly adheres to ISO 13485 and EN 13795 standards, ensuring high safety, consistency, and quality suitable for critical applications. The hypoallergenic nature and non-irritant surface of the fabric make it safe for prolonged skin contact, making it the preferred choice for disposable medical and hygiene products.

Customized for Versatility

Available in a broad spectrum of weights (20120 GSM), colors, dimensions, and lamination options, our NonWoven SMS Fabric can be tailored to meet specific requirements for medical, industrial, or hygiene applications. Ultrasonic or stitched edge finishes and antibacterial, antistatic, hydrophobic, and lamination treatments further enhance its adaptability.

FAQs of NonWoven laminated SMS fabric:

Q: How is NonWoven Laminated SMS Fabric commonly used in medical and industrial settings?

A: This fabric is widely employed for making gowns, drapes, masks, coveralls, and disposable sheets, providing reliable barrier protection against fluids and particles in healthcare, laboratories, and industrial safety environments.Q: What benefits does the PE or PP film lamination provide?

A: PE or PP film lamination increases fluid and particle resistance, resulting in high water repellency (over 80%), without compromising the fabrics breathability or soft touch.Q: When should you choose customized GSM, color, or lamination options?

A: Opt for customization when specific application needs must be metfor example, different GSM for varying strength or breathability, colors for identification, and specialized lamination for unique barrier requirements.Q: Where is this fabric manufactured and supplied?

A: This SMS nonwoven laminated fabric is produced and supplied by dealers, distributors, fabricators, exporters, manufacturers, producers, retailers, traders, and wholesalers throughout India, with custom orders available for international clients.Q: What sterilization methods are compatible with this material?

A: It can be sterilized by Ethylene Oxide (EO), Gamma irradiation, or Steam, making it suitable for reusable or disposable medical products.Q: How does the structure ensure user safety and comfort?

A: The 3-layer SMS structure, combined with lamination, offers a high microbial and particle barrier while remaining hypoallergenic, soft, non-irritant, and breathable for extended wear.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hospital Equipment Category

patient transfer sheet

Price 335.5 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : laminated fabrics

Application : for safe patient transfer

Use : for safe transfer

Shape : rectangle

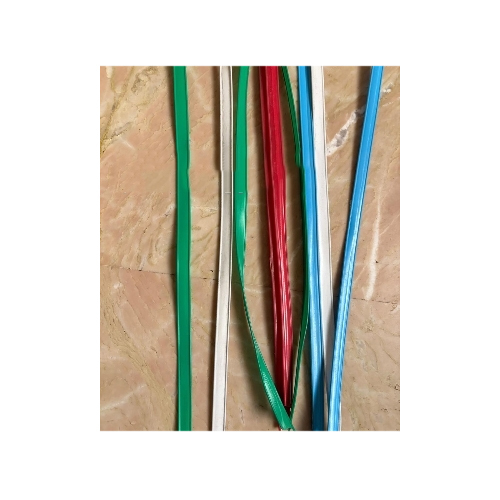

Drape making wire (flexible)

Price 225.0 INR / Meter

Minimum Order Quantity : 5000

Material : wire inbuilt PVC

Application : pouch positioning

Use : pouch mouth openor

Shape : rectangular

sanitizer 5litre

Price 550.00 INR / Pack

Minimum Order Quantity : 5 Packs

Material : Alcoholbased formulation

Application : Hand Disinfection

Use : Direct use on hands without water

Shape : Can/Bottle

Non Woven SMS

Price 188 INR / Kilograms

Minimum Order Quantity : 20 Kilograms

Material : SMS (Spunbond + Meltblown + Spunbond) Fabric

Application : Medical, Hygiene, Industrial, Surgical Gowns, Drapes

Use : Disposable

Shape : Rolls or sheets

GST : 07COHPM6666P1Z0

|

|

STERIKARE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry